Evolution of electrical safety in Italy

One of the things that becomes very apparent once you start learning about vintage electrical devices

is just how unsafe they were. It was so easy to come into contact with live parts accidentally, and

back then they didn't have things like RCDs (aka GFCIs) to save you.

Because of this, I thought it would be interesting to take a look at various electrical items throughout

the years and analyse their safety, or lack thereof.

Italy in particular seems to have started caring about safety later than other European countries did - for example, the use of fuses or breakers wasn't even mandatory until the 60s! Of course, nobody in their right mind would even think about going without them, but this shows that, presumably, back then they didn't have strict electrical codes. Safety improved considerably only in the 80s/90s, and before then I presume that it was just up to the installer whether to buy products that had certain safety features or to go with a cheaper option.

The old times

Let's start by taking a look at some devices used in the 30s and 40s (the pictures were found in an old book I have).

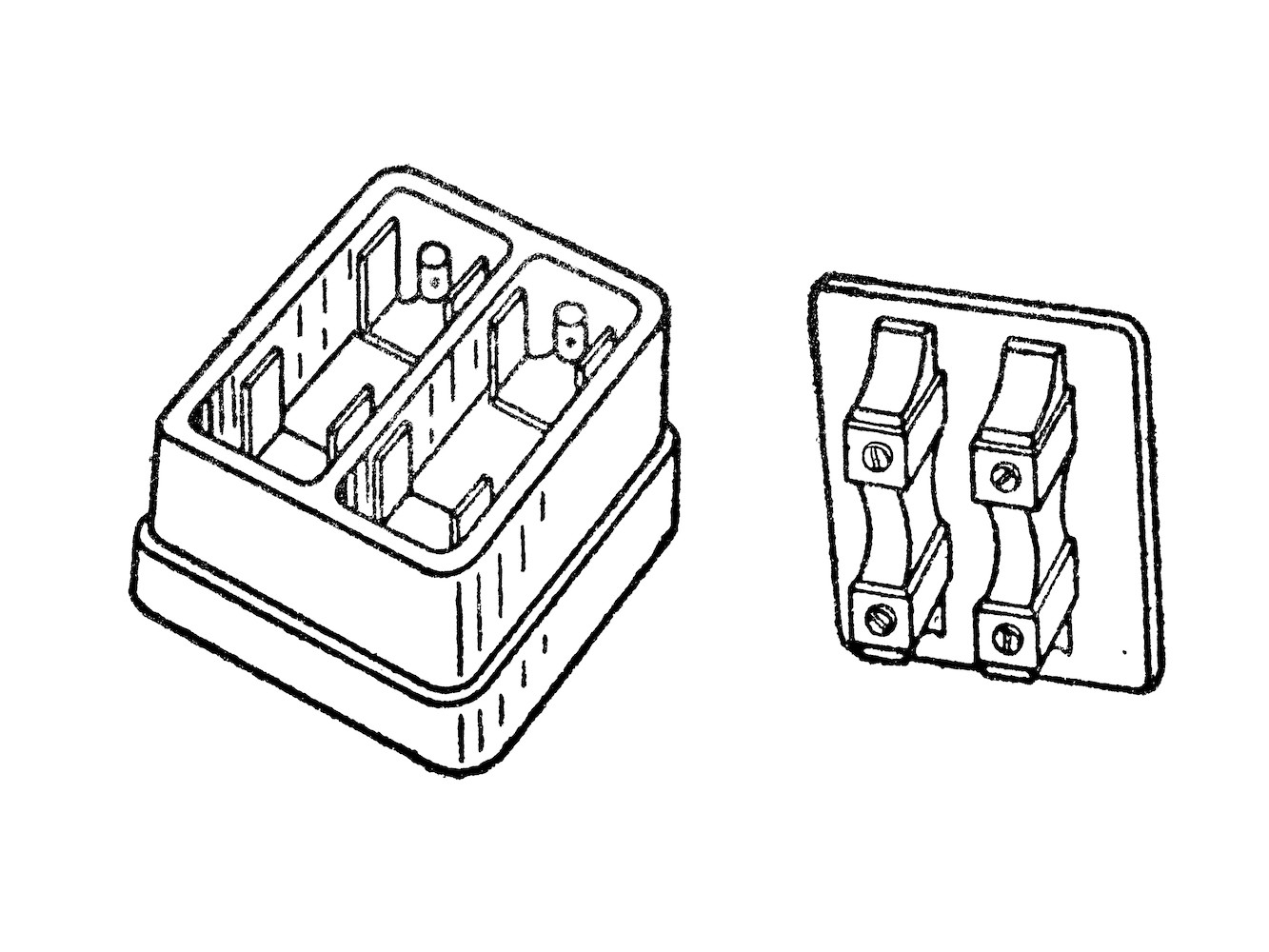

The power sockets remained the same for many years, with safety features only being added in the 70s, so

the only distinctive feature older ones have is their material, which was generally ceramic or bakelite.

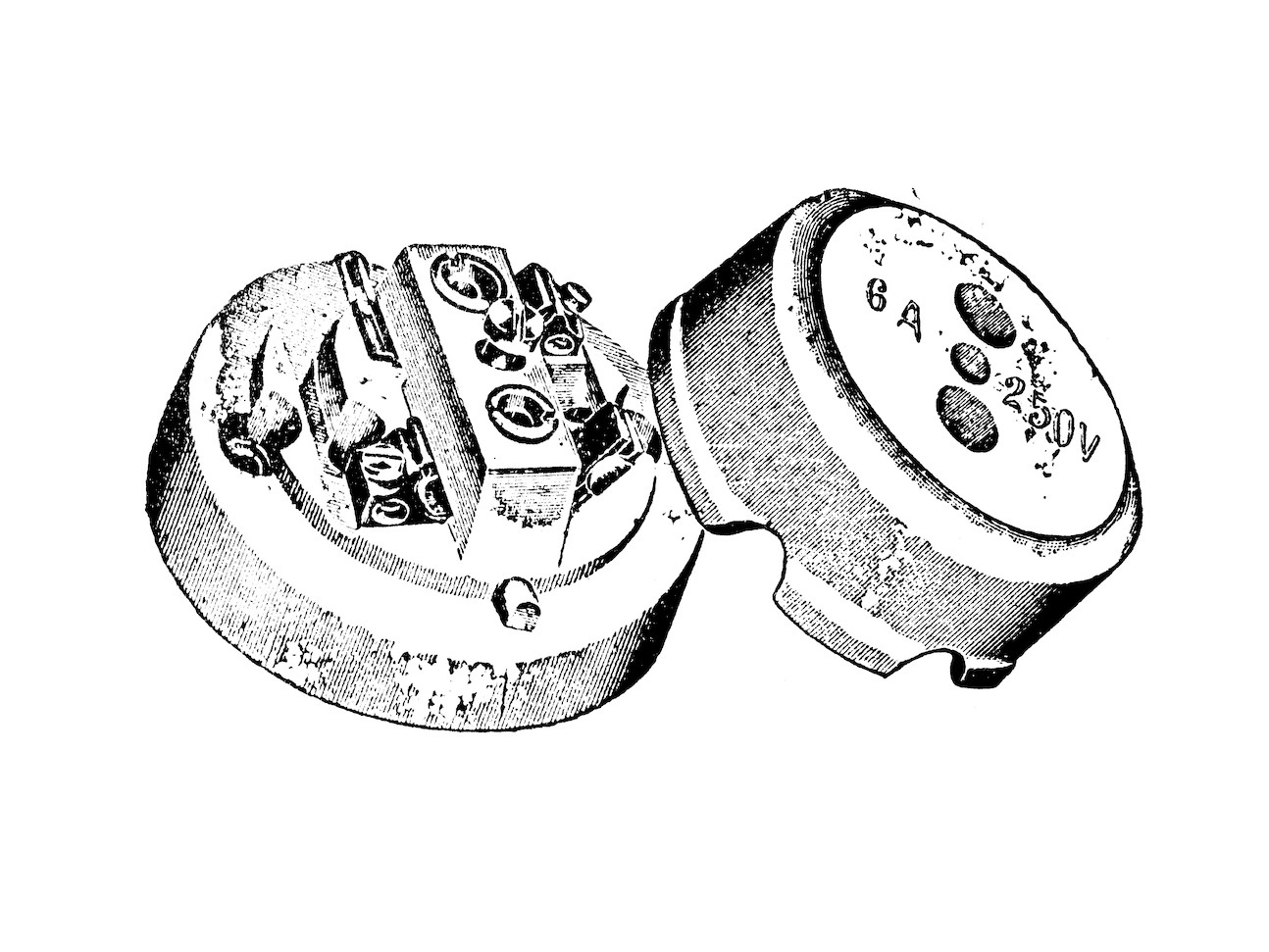

It's interesting to note that the socket in the last image has actually a place for a fuse - from my understanding,

this was sometimes done to save money on copper during the early days of electrification, so you could have a

bigger circuit for the entire house and have each device protected with its own fuse.

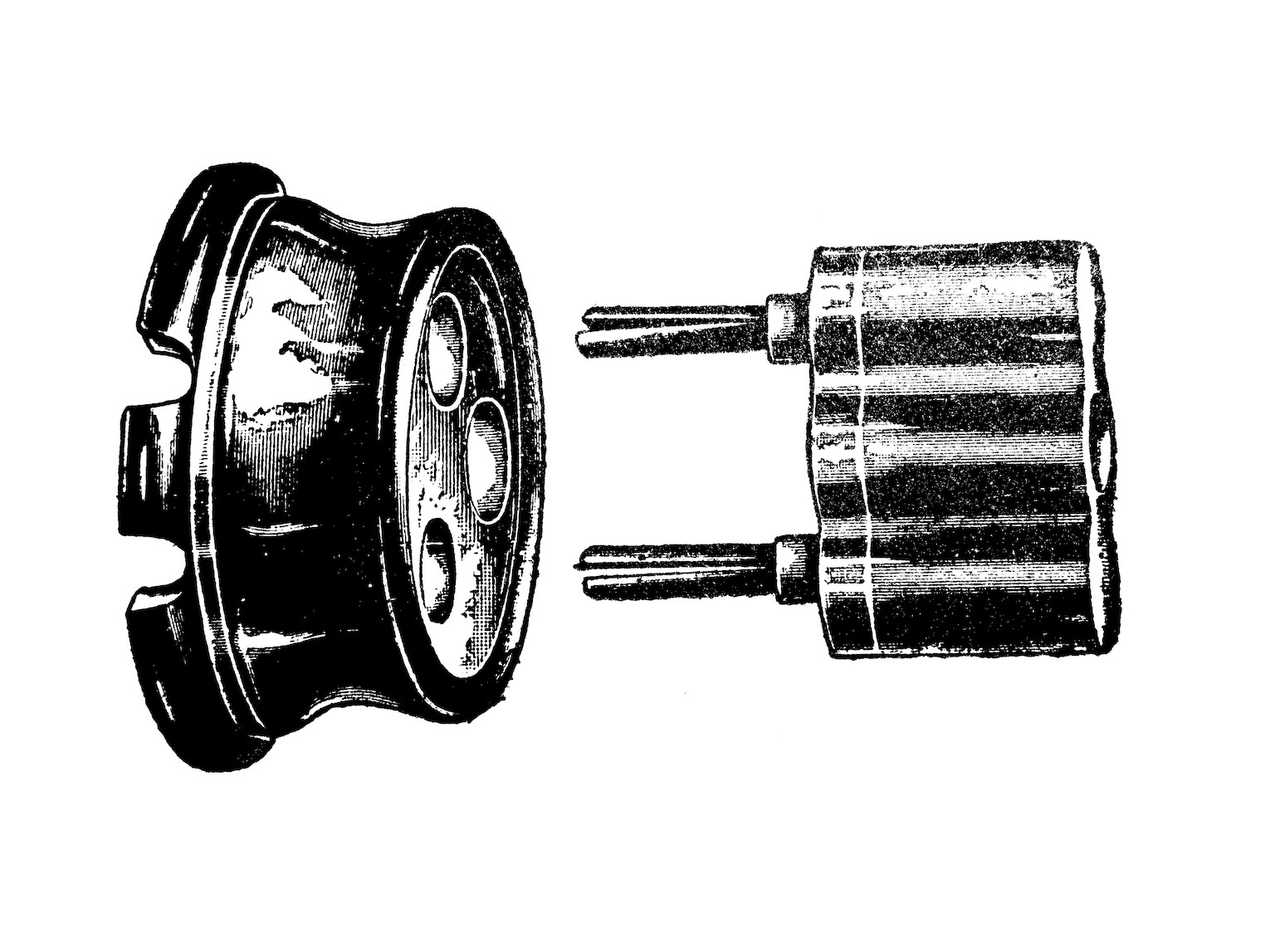

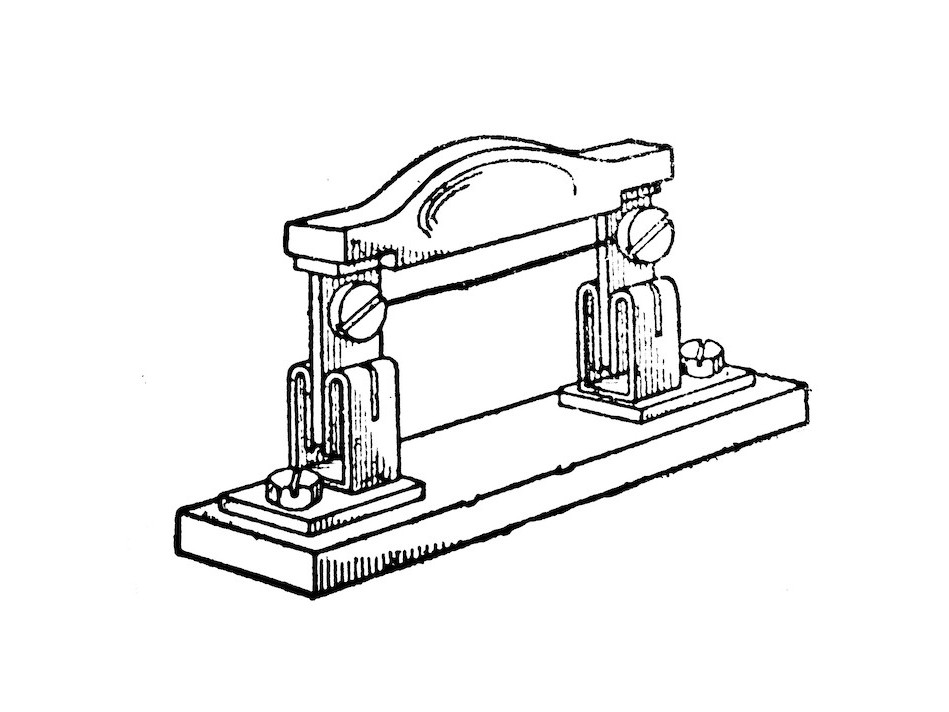

The fuse holders used at the time, on the other hand, were considerably less safe than the ones used in later years.

The one in the first picture had a porcelain or bakelite lid that unscrewed to reveal the fuse wire, which could only be changed when the power was off. Of course, there was nothing preventing the user from trying to change the fuse with the power still on, which could have lead to a shock.

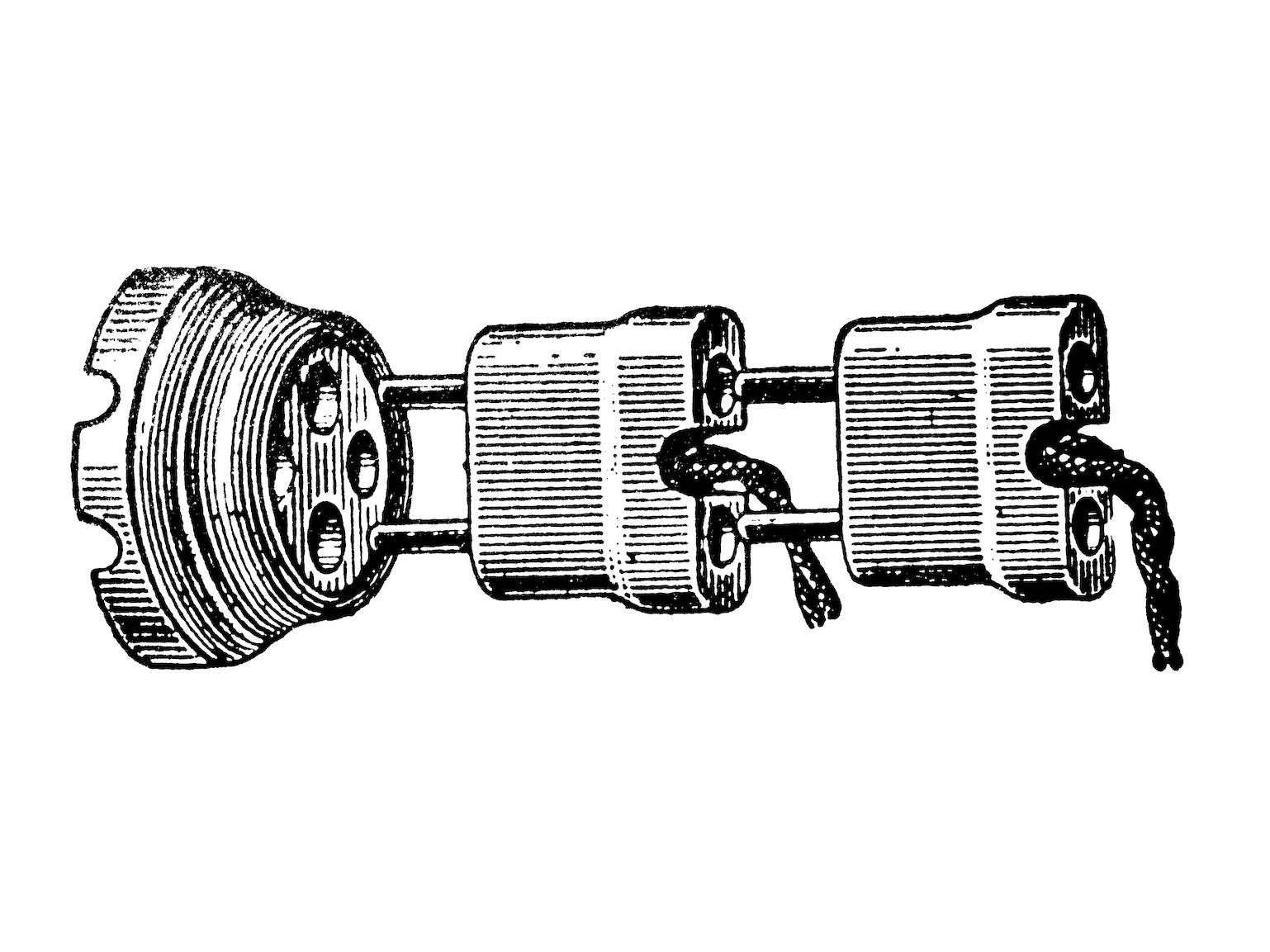

Other models, like the ones in the second and third pictures, held the fuse wire in a removable lid, so

the fuses could have been, theoretically, removed and changed even with the power still on.

However, some models were better than others in that regard - the device in the third picture left a lot

of metal exposed, and it could have been easy to accidentally come in contact with it when changing the fuse.

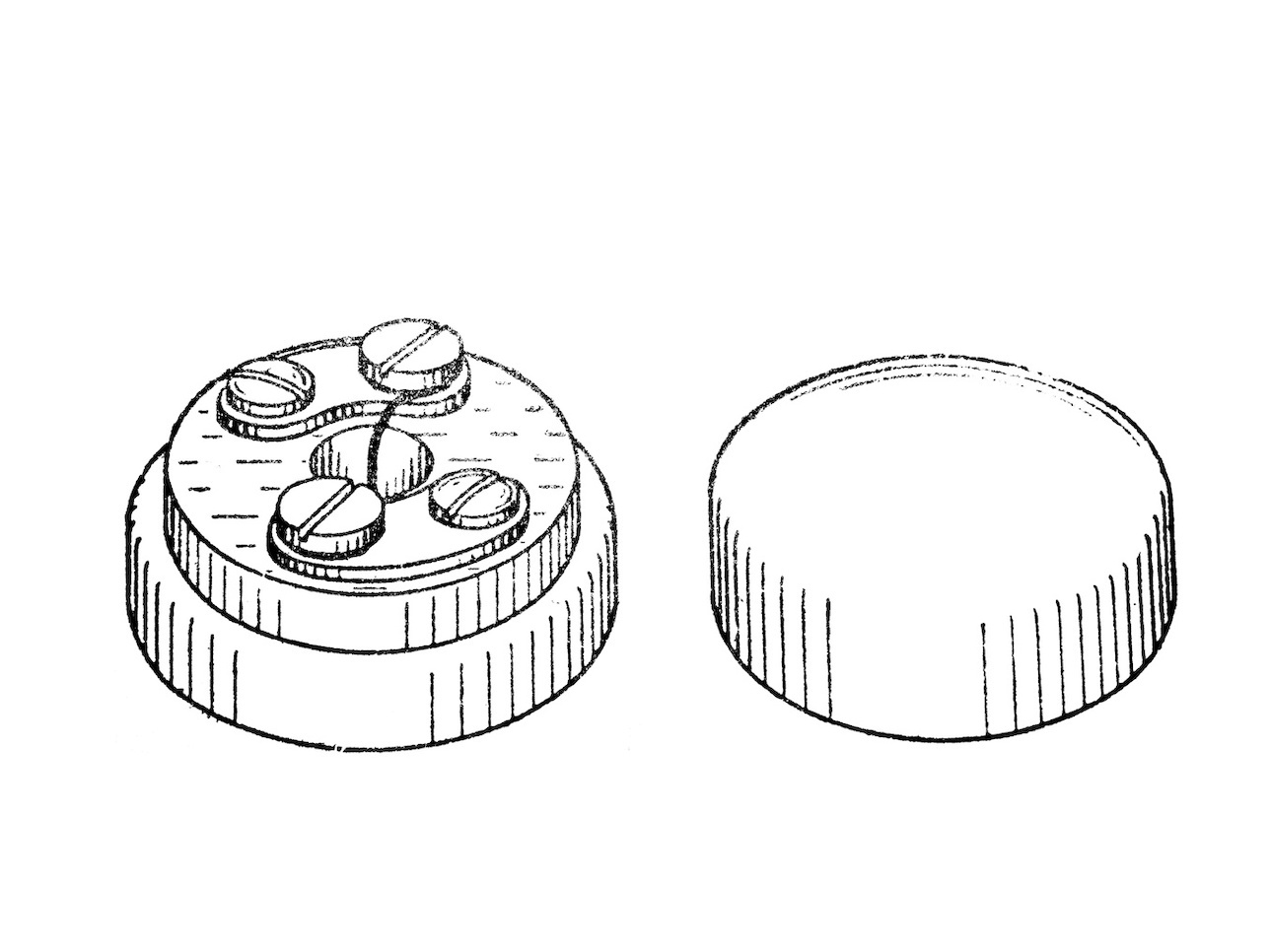

Finally, there were also some fuses that screwed into place, an option which became more common later on.

Fuse panels

However, all of these items had the same flaw: it was very easy to come into contact with the live contacts. Many fuse holders, like the one in picture 4, had the connection screws exposed, which mean that you had to pay attention not to touch them accidentally when changing a fuse.

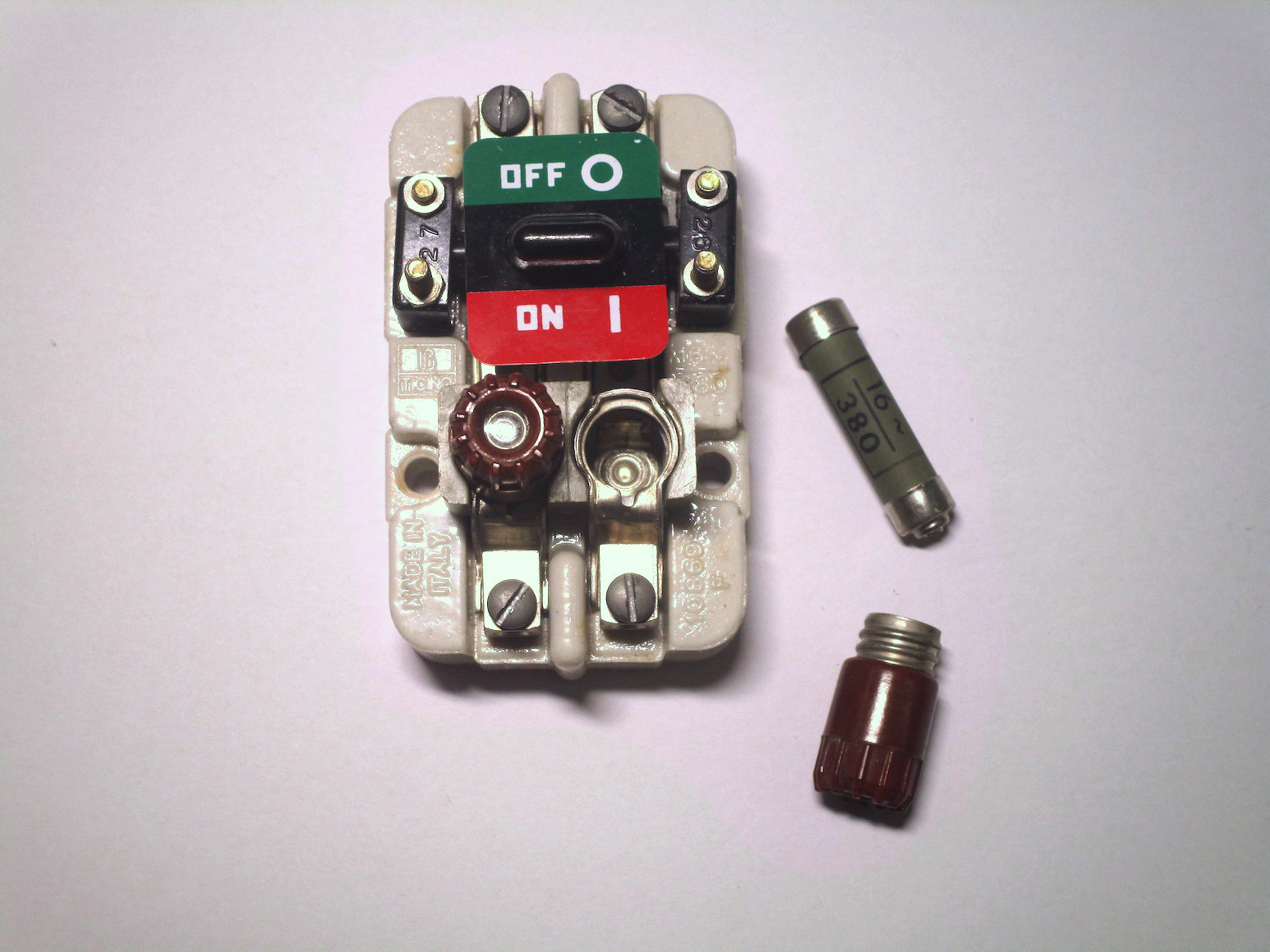

In the 50s the company BTicino started selling a line of fuse holders that was very popular which had

some considerable safety improvements over the ones showed above: each fuse holder had its own shut-off

switch, to cut the power before changing a fuse.

The fuses used were of the cartridge type (although there was also a version available which used rewireable

fuses), which is generally easier to change than a fuse wire.

And, most importantly, all the connections were housed inside of the plstic or metal case of the

fuse holder itself, which made accidental contacts much less likely.

These devices weren't without their own flaws, however: while they were much safer, there was nothing preventing you from turning on the power switch while a fuse wasn't inserted. Later models were available with a lid which covered the fuses unless the power was switched off, however this wasn't commonly found in the home, instead seeing more use in industrial applications.

Plus, another safety issue found with most kinds of fuses was the possibility of changing the fuse with another one of a different rating. In North American fuse panels you sometimes saw people using pennies to replace a blown fuse, and, well, there was certainly an equivalent of that over here as well.

This problem didn't necessarily have to exist, as it's quite easy to design cartridge fuses so that

the holder only accepts fuses of the right rating - this was the case with the Diazed fuse system used

extensively in the rest of continental Europe, but those were considerably less popular over here.

Ultimately, this would only be solved by the use of breakers instead of fuses, but that only happened

years later.

Plugs and sockets

Plugs and sockets took a while to improve, safety-wise. Of course, the materials and the design of them

changed over time, but for many years there weren't substantial safety benefits between a plug from, say,

the 30s, and one from the 60s, apart from maybe a slightly easier to hold design.

And, given that, compared to fuses, plugs are something that people actually use and handle every day, I wouldn't

be surprised if that was one of the easiest ways to get a shock back then.

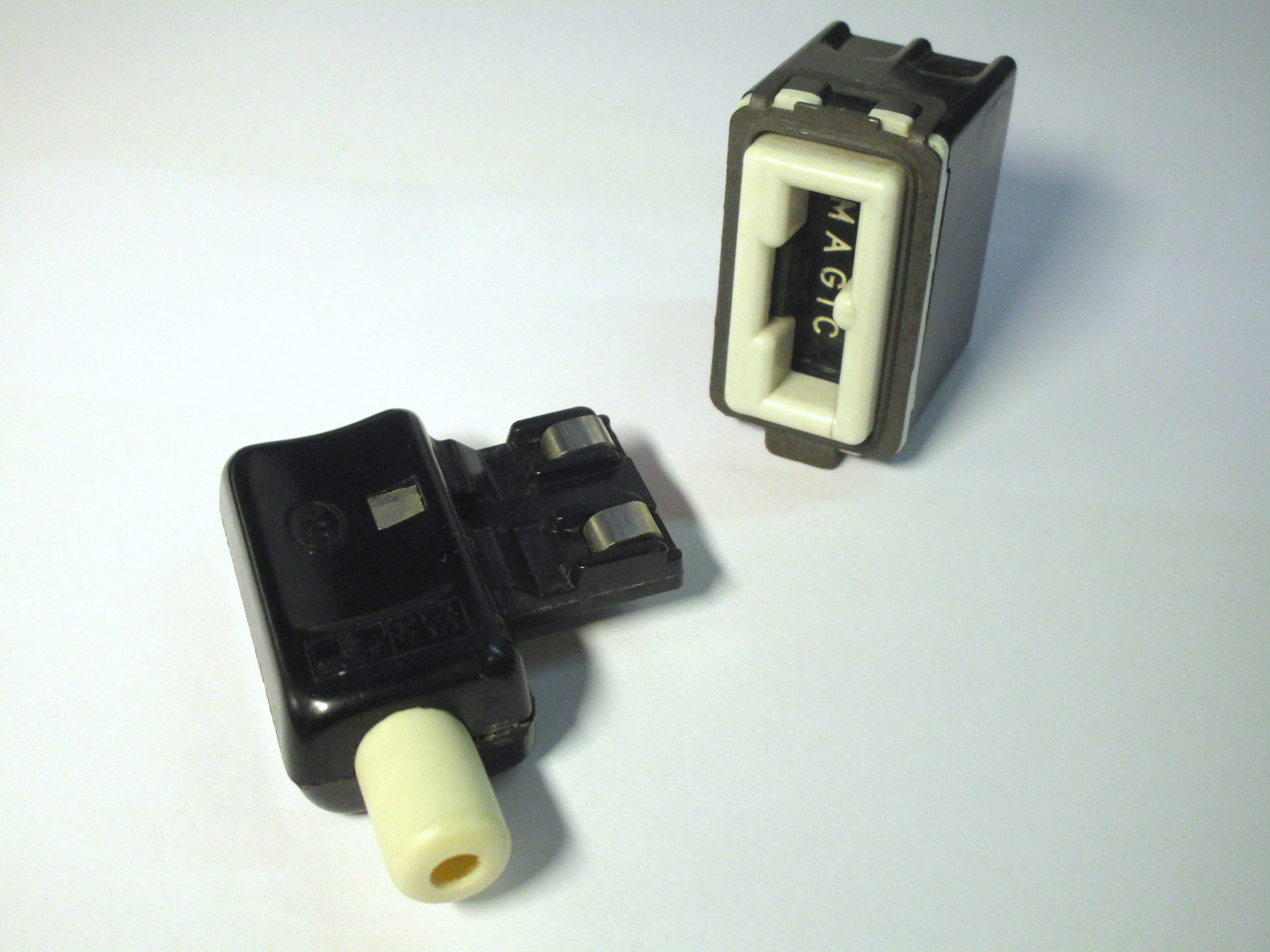

This lead to a dissatisfaction with the current standard of plugs, which was apparently one of the

inspiring factors behind the creation of the Magic plugs and sockets.

They were primarily designed to be safe, and this part of their design is still perfectly valid even today

(although they aren't in use anymore).

The most significant safety feature they added was the introduction of shutters in sockets. A complicated

mechanism meant that the only thing that could open the (single) shutter was the plug itself.

The plug itself, on the other hand, was made so that it was impossible to touch any exposed metal if it

wasn't inserted fully.

These safety features were the main selling point of the Magic plugs - however, in the following years the

normal Italian plugs also started changing to be safer, by adopting shutters (with the Vimar Sicury patent)

and adding protective sleeves on the pins.

So, the Magic plugs had lost most of their advantages.

Residual Current Devices

Aka: GFCIs, RCCBs

One of the biggest contribution in safety has, of course, been the introduction and adoption of the RCD.

They have been mandatory in Italy for decades, and for a very good reason: they actually help save lives.

One of the biggest contribution in safety has, of course, been the introduction and adoption of the RCD.

They have been mandatory in Italy for decades, and for a very good reason: they actually help save lives.

A very early model of RCD sold here was the BTicino Salvavita (="life saver").

This name has become so common that it has actually become the term used in Italy to refer to RCDs.

Early Salvavitas were both breakers and RCDs, however later on "plain" RCDs were also available, which can

be connected to multiple breakers for multiple circuits, helping reduce the cost of the installation while

keeping it secure.

Modern RCDs are current-operated: that is, if they sense a difference in current of a certain level (typically 30mA) between line and neutral, they trip and shut off the power. The trip current is such that, in case a person accidentlly comes in contact with a live wire, the device will operate and prevent electrocution.

Note that in some other countries, notably the UK, VOELCBs - that is, voltage-operated earth leakage circuit breakers, were used in certain circumstances. These devices worked differently than RCDs, as they sense a voltage difference betweeen the circuit earth and the "real" earth, and, in countries where they were used, were meant primarily for TT installations, where a fault from live to earth wouldn't necessarily blow the fuse or trip a breaker.

The main disadvantage to them is that they didn't protect the user from an electric shock, and thus were replaced by current-operated devices (RCDs) which do offer that protection.

Safety nowadays

Modern Italian electrics are generally similar in safety as other EU countries. RCDs have been made mandatory not just in new installations but also in old ones, and shutters in sockets have been mandatory for decades (something that's still not the case in every European country, unfortunately).

However, older installations are still present, and even though they should all have RCDs now, that doesn't solve all the other problems they might have: old sockets without shutters, undersized cabling, lack of earth protection... But thankfully installations like that are getting fewer and fewer as new ones are built and older houses are renovated.